Fermentation Timeline: What to Expect as You Brew

Understanding the fermentation timeline is crucial for you as a brewer, whether you re crafting beer, wine, or other delightful fermented beverages using your brewing kit. Get ready to explore the exciting steps of fermentation and elevate your brewing skills!

This article breaks down the process into distinct fermentation phases, starting from the initial lag phase and moving through to the robust secondary fermentation. You’ll explore key factors that influence fermentation, such as temperature, yeast strain, and primary fermentation temperature, along with methods for monitoring your progress.

The article addresses common issues like over-carbonation, providing practical solutions to keep your brew on track.

Contents

- Key Takeaways:

- The Fermentation Timeline

- Factors That Affect the Fermentation Timeline

- 1. Temperature

- 2. Yeast Strain

- 3. Sugar Content

- 4. Oxygen Levels

- How to Monitor the Fermentation Process

- Common Issues During Fermentation

- How to Troubleshoot and Fix Issues

- 2. Adding Nutrients and Monitoring Yeast Health

- 3. Sanitizing Equipment

- Frequently Asked Questions

Key Takeaways:

- The fermentation timeline consists of 5 phases: lag, exponential growth, stationary, death, and secondary fermentation.

- Factors such as fermentation temperature, yeast strain, sugar content, and oxygen levels can affect the fermentation timeline and final product.

- Monitoring specific gravity (which measures the sugar content in your brew), visual cues, and smell/taste can help track the fermentation process. Common issues include stuck fermentation, off-flavors, and infection, which can be troubleshooted by adjusting temperature, adding nutrients, and sanitizing equipment.

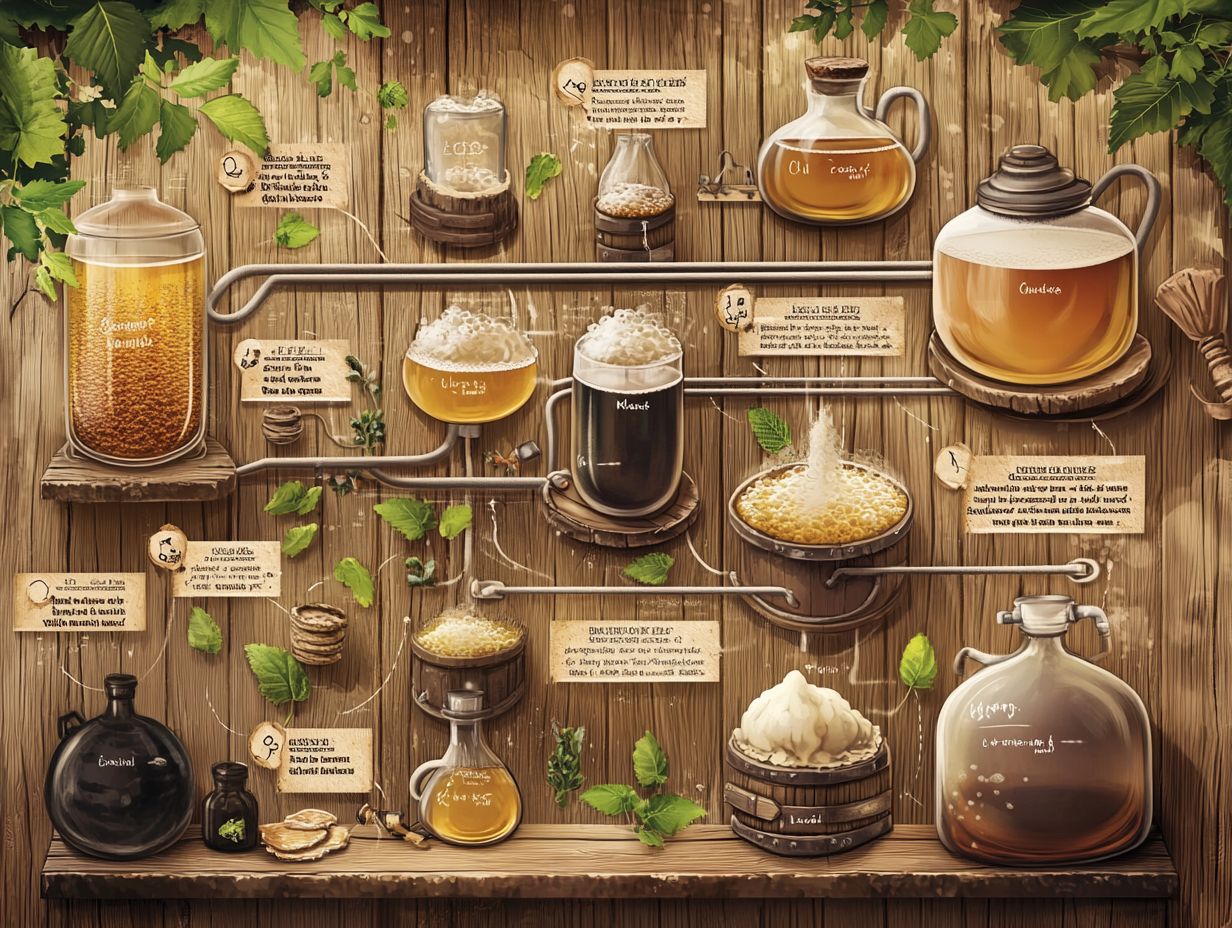

The Fermentation Timeline

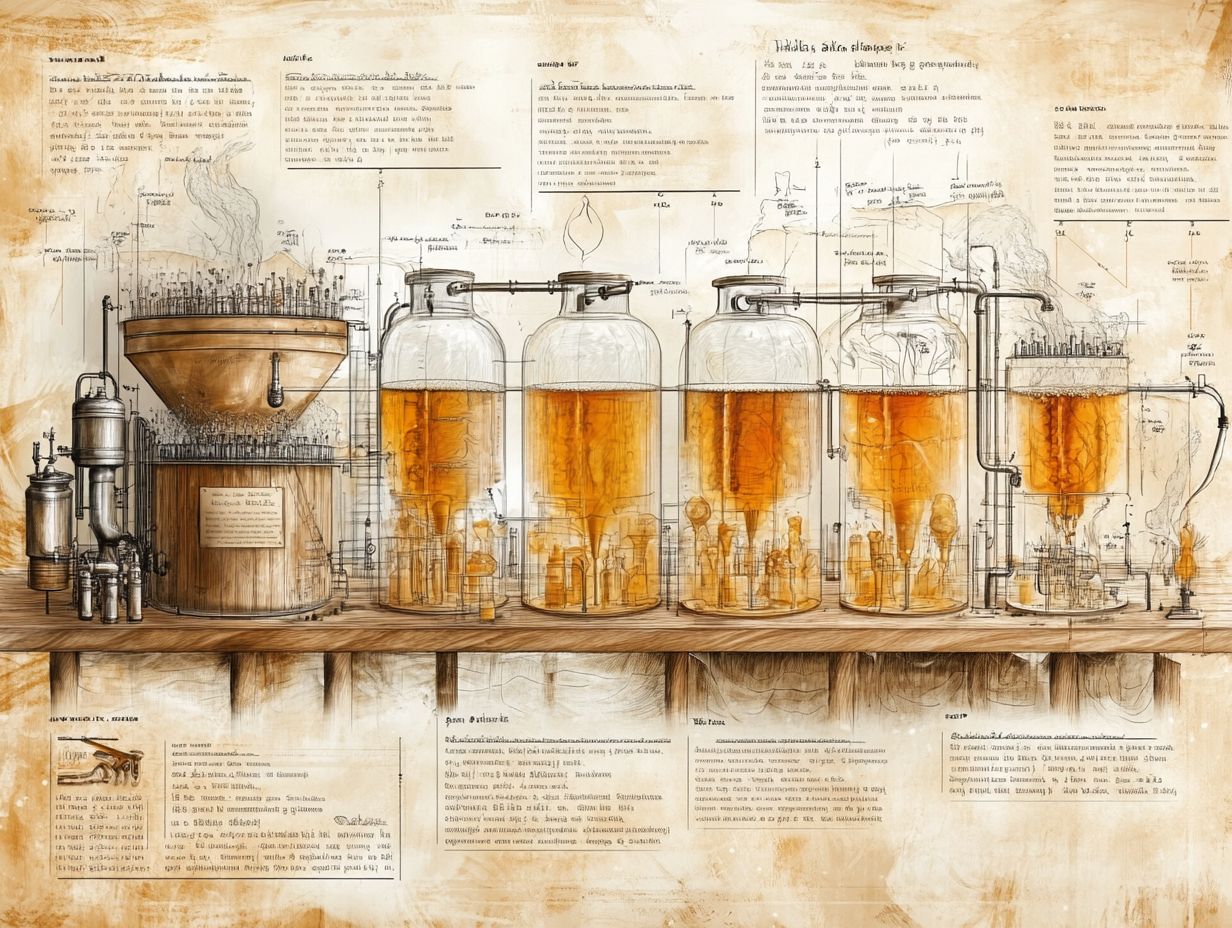

The fermentation timeline is an essential element of the brewing process that significantly influences the quality and flavor of the beer you create. This timeline consists of several distinct phases: the lag phase, exponential growth phase, stationary phase, death phase, and secondary fermentation.

Each phase is crucial for yeast metabolism, growth, and the development of flavor compounds, which are vital for both homebrewing enthusiasts and professional brewers. By understanding the fermentation timeline, you can effectively monitor yeast health, specific gravity, and overall fermentation activity, ensuring a successful brewing experience whether you re working with a glass carboy or a larger primary fermentor and other fermentation vessels.

1. The Lag Phase

The lag phase marks the initial stage of fermentation, where yeast cells take the time to acclimate to their new environment, gearing up for the active fermentation process and krausen formation. During this phase, they carefully assess their surroundings, gather essential nutrients, and kick off signals that help yeast grow, which are crucial for their growth.

Optimal conditions, such as temperature, pH, and nutrient availability, play a pivotal role here, as they directly impact yeast health and reproductive activity during the fermentation process. As the yeast absorbs these vital elements from the medium, they get ready to reproduce, setting the stage for the dynamic fermentation that follows.

Grasping these fermentation dynamics is essential; a healthy and well-prepared yeast population is key to ensuring a robust and efficient fermentation process, which ultimately influences the quality of the final product and the success of alcohol fermentation.

2. The Exponential Growth Phase

During the exponential growth phase, yeast cells reproduce rapidly and display heightened fermentation activity, leading to a remarkable production of CO2 through active yeast metabolism. This critical stage is marked by a vigorous metabolic rate, where your choice of yeast strain can significantly impact the entire fermentation process.

Yeast metabolism is particularly sensitive to temperature fluctuations; maintaining an optimal range can enhance the flavor profile of your brew, whereas extremes might result in undesirable esters, diacetyl, or off-flavors. It s essential for you to monitor both temperature and yeast health during this phase, as these factors dictate not only the efficiency of fermentation reactions but also the aromatic compounds produced, ultimately shaping the distinct flavor and character of your beer.

By ensuring stable conditions, you can unlock the full potential of your selected yeast, allowing you to create delightful and complex beer varieties that truly stand out.

3. The Stationary Phase

The stationary phase presents a delicate equilibrium between yeast growth and the inevitable demise of yeast cells, resulting in the accumulation of byproducts of fermentation such as diacetyl.

During this pivotal period, the dynamics of yeast clumping become crucial to the brewing process. As yeast cells clump together and settle, their collective activity has a profound impact on the clarity and flavor profile of your final product.

It’s essential to monitor fermentation byproducts closely, as they can influence not just the taste but also the aroma and mouthfeel of your brew. Compounds like acetaldehyde and esters may emerge during fermentation, adding layers of complexity to the beer.

By keeping a vigilant eye on these elements throughout the stationary phase, including yeast clumping and krausen formation, you ensure a meticulously crafted outcome that embodies your brewing intent and highlights the unique characteristics of the yeast you’ve chosen.

4. The Death Phase

In the death phase, you ll notice a significant decrease in yeast viability, which can introduce a host of fermentation challenges, such as over-carbonation, if not managed with care. This phase often necessitates the use of yeast nutrients to maintain yeast health.

This phase can be tricky, but with careful management, you can overcome these challenges and craft a fantastic brew.

Understanding the factors that contribute to this decline is essential for achieving optimal brewing outcomes. Temperature, for instance, plays a pivotal role in yeast health; subjecting your yeast to extreme heat or cold can stress the cells, leading to reduced fermentation efficiency and undesirable flavors. Proper temperature control is critical during each of the fermentation stages to ensure success.

You must also keep a close eye on nutrient levels, including vital vitamins and amino acids. If your yeast doesn t receive enough nutrients, it may become sluggish or even perish prematurely, negatively affecting not just the fermentation process but the overall quality of your final product.

Therefore, maintaining a careful balance of environmental conditions is critical for nurturing robust yeast activity and managing fermentation reactions throughout your brewing journey.

5. The Secondary Fermentation Phase

The secondary fermentation phase is where your beer truly comes into its own. Here, flavors mature, and brewing sugars are consumed, often resulting in a clearer and more refined brew.

During this crucial stage, your brewing process receives a significant boost from the active yeast, which diligently metabolizes those residual sugars. This not only produces additional flavor compounds but also enhances the overall complexity of your beer.

This aging period plays a pivotal role in developing desirable aromas and encourages the natural carbonation process through bottle conditioning during the conditioning phase.

As carbon dioxide is generated, it seamlessly integrates with the beer, contributing to a smoother mouthfeel and a well-rounded taste. Keeping your yeast healthy during this phase is imperative; vibrant, active yeast can help eliminate off-flavors and ensure a clean finish during lager fermentation.

This attention to detail ultimately leads to a superior quality brew that is more satisfying to the palate.

Factors That Affect the Fermentation Timeline

Numerous factors play a crucial role in shaping the fermentation timeline. You’ll want to consider elements such as fermentation conditions, the selection of yeast strain, fermentation temperature, sugar content, and the levels of oxygen present in your brewing environment. The type of fermentation vessels you use, such as a primary fermentor or glass carboy, also impacts the process.

Each of these aspects can dramatically influence the outcome of your fermentation process.

Now that you understand these phases, why not give brewing a go? Your next favorite beer could be just a batch away!

1. Temperature

Temperature plays a pivotal role in your yeast growth and fermentation activity, directly influencing the speed and efficiency of the fermentation process.

You ll find that different yeast strains excel at varying optimal fermentation temperatures. Some thrive in cooler environments, while others perform best in warmer conditions. Striking the right balance within these temperature ranges is crucial, not just for maximizing yeast health, but also for crafting the distinct flavor profiles you desire in the final product.

For example, ale yeast typically ferments best between 65 F and 75 F, producing delightful fruity esters. In contrast, lager yeast prefers the cooler range of 45 F to 55 F, resulting in a cleaner, crisper taste. Be mindful that fluctuations in temperature can stress the yeast, leading to off-flavors or stalled fermentation during primary fermentation. This underscores the importance of maintaining stable conditions throughout your brewing process.

2. Yeast Strain

The choice of yeast strain is crucial in shaping the fermentation conditions and the flavor profile of your beer, as each strain brings its own unique fermentation characteristics to the table.

For example, ale yeast thrives at warmer temperatures, enabling a quicker fermentation process that encourages the development of fruity esters and phenolic compounds. In contrast, lager yeast prefers cooler temperatures, resulting in a more gradual fermentation that produces a clean, crisp flavor profile.

Both types of yeast not only contribute to the taste and aroma of the final product but also play essential roles at various stages of the fermentation timeline, influencing flavor, color, clarity, and mouthfeel. High krausen during fermentation is a good indicator of active yeast growth.

By grasping these nuances, you can significantly elevate your brewing game and craft distinctive, flavorful beers that stand out.

3. Sugar Content

Sugar content, including maltose and other wort sugars, plays a pivotal role in the fermentation process.

The different sugar levels in your ingredients can greatly affect fermentation rates, which, in turn, shapes the flavor development by influencing yeast growth and the overall fermentation timeline of your final product. For instance, when you have a high concentration of simple sugars like glucose, yeast tends to ferment these rapidly, resulting in a quicker primary fermentation phase and a lighter flavor profile.

On the flip side, sugars that are not easily broken down, like dextrins, can slow down fermentation, allowing for a rich tapestry of flavors to unfold over an extended period, especially during the secondary fermentation phase. Grasping these dynamics is essential for you as a brewer, especially when striving to strike the perfect balance between sweetness, alcohol content, and overall flavor complexity in your craft, particularly in styles like a Belgian tripel or an ale.

4. Oxygen Levels

Oxygen levels before and during fermentation play a crucial role in influencing fermentation activity and yeast metabolism. If not managed properly, they can lead to off-flavors in your brew.

The right balance of oxygen during brewing is vital for keeping your yeast healthy and ensuring proper yeast reproduction. This balance supports their growth while steering clear of any negative effects. Too much oxygen can create unwanted byproducts, such as excessive esters and phenols, jeopardizing the intended flavor profile of your beverage. Insufficient oxygen can stress the yeast, causing incomplete fermentation and off-flavors.

That s why it s essential for you to diligently monitor oxygen levels throughout the entire brewing process, understanding their direct impact on fermentation dynamics, yeast vitality, and ultimately, the overall quality of your final product, preventing issues like over carbonation.

How to Monitor the Fermentation Process

Monitoring the fermentation process is essential for you as a brewer, enabling you to maintain optimal yeast health and sidestep potential fermentation issues. You can achieve this through a variety of methods, including:

- Measuring specific gravity with a hydrometer or refractometer

- Paying attention to visual cues

- Assessing both smell and taste

Each of these techniques provides valuable insights that can significantly impact the quality of your brew. Start monitoring your fermentation today and watch your brewing skills soar!

1. Specific Gravity

Specific gravity serves as a pivotal measurement in the brewing process, providing insight into fermentation activity, yeast metabolism, and the density of the wort as it evolves.

By regularly taking specific gravity readings with a hydrometer, you can effectively monitor the sugar content in the wort and gain valuable insights into yeast metabolism. In the early stages, as yeast actively converts sugars into alcohol, you ll notice the specific gravity decreasing as fermentation progresses.

Interpreting these readings is crucial; it allows you to determine when fermentation is nearing completion or has reached its final gravity. This knowledge is essential for achieving the desired characteristics in your finished beverage.

Understanding specific gravity directly impacts your brewing outcomes, enabling you to make informed decisions regarding flavor profiles, carbonation levels, yeast health, and overall quality.

2. Visual Cues

Observing visual cues like krausen formation and high krausen can offer you valuable insight into the fermentation activity and overall health of your yeast. This frothy layer of bubbles, primarily made up of proteins and yeast, is a clear sign that the fermentation process is in full swing, showcasing vigorous metabolic activity.

As fermentation progresses, you may notice a shift in color, often deepening or transforming into shades that reflect the ingredients you’ve used, such as richer hues from malt or fruit, indicative of active fermentation reactions. The emerging bubbles not only indicate the production of carbon dioxide but also provide a glimpse into yeast health; consistent bubbling suggests robust yeast vitality, while a lack of activity may raise a flag for potential issues.

By understanding these visual indicators, you can effectively monitor the fermentation process, making necessary adjustments to ensure a successful batch, whether you are using a primary fermentor, glass carboy, or other fermentation vessels.

3. Smell and Taste

Assessing the aroma and flavor of your beer can unveil vital insights into the fermentation process, shedding light on potential byproducts and the evolution of flavor compounds such as esters and phenols.

While concrete measurements like specific gravity deliver solid data about alcohol content and sugar levels, they often miss the delicate nuances that shape a beer’s overall character, including byproducts of yeast flocculation. Sensory evaluation beautifully complements these figures by capturing the intricate symphony of aromas and flavors that emerge during fermentation. By thoughtfully engaging with scent and taste, you can uncover subtle notes of fruity esters, spicy phenols, and even those pesky off-flavors that might slip past numerical analysis.

Ultimately, the art of tasting enables you as a brewer to refine your craft, ensuring that each batch aligns with your vision and elevates the drinking experience to new heights during the conditioning phase.

Common Issues During Fermentation

Brewing can present its fair share of challenges, and you may encounter various issues during fermentation. These can include stuck fermentation, unwanted off-flavors that compromise the integrity of your brew, and the risk of infections that could spoil the entire batch.

1. Stuck Fermentation

Stuck fermentation happens when your yeast doesn t quite finish the job, often due to less-than-ideal yeast health or fermentation conditions that are just off, including poor primary fermentation temperature control.

Several factors can contribute to this issue, including temperature fluctuations, insufficient yeast nutrients, or an overly acidic environment. Recognizing the signs of stuck fermentation is essential for any brewer, whether you’re homebrewing or using a commercial brewing kit. You might notice it when there s a lack of bubbles in the airlock, an unusual sediment layer forms, or you detect an unexpected sweetness in your final product.

To tackle this problem, consider exploring various troubleshooting strategies, such as pitching additional healthy yeast, adjusting the temperature, or ensuring that your fermentation vessel is properly aerated. Making it a habit to conduct regular checks on yeast vitality can go a long way in preventing these issues in the future.

2. Off-flavors

The presence of off-flavors in your beer, like diacetyl, can stem from various fermentation byproducts and may signal underlying issues with your yeast strain or fermentation conditions.

These unwanted flavors often arise from poor fermentation management, including insufficient oxygen levels, suboptimal fermentation temperatures, or stressed yeast. Take diacetyl, for example: it’s typically produced as a byproduct of yeast metabolism, which can overshadow the intended profile of your brew.

To avoid such pitfalls, it s crucial to monitor fermentation closely, including careful monitoring of fermentation stages. Regularly check the temperature and the health of your yeast to ensure the conditions are conducive to proper fermentation.

Maintaining a clean brewing environment can significantly reduce the risk of other common off-flavors, such as sulfur compounds and phenolic notes, allowing the desired flavor compounds to truly shine through.

3. Infection

Infection during the fermentation process can introduce undesirable flavors and aromas. This often stems from inadequate sanitation practices in your brewing routine.

When unwelcome microorganisms, like wild yeasts and bacteria, find their way into your brewing environment, they can significantly disrupt the intended flavor profile of your beer. This affects fermentation activity and can lead to unwanted byproducts like diacetyl.

These infections tend to thrive in dirty equipment or as a result of careless handling, leading to sour or off-flavors that compromise the overall quality of your product.

To mitigate these risks, it s essential for you to follow strict sanitation protocols, ensuring that all surfaces and tools are carefully cleaned and sanitized before use. By implementing precise brewing techniques such as controlling temperature and closely monitoring fermentation you can further reduce the risk of contamination.

This ultimately allows you to achieve a more consistent and enjoyable final product, particularly during lager fermentation.

How to Troubleshoot and Fix Issues

Troubleshooting and resolving fermentation issues demand a methodical strategy. This involves fine-tuning the temperature, incorporating yeast nutrients, and ensuring that all your equipment is thoroughly sanitized.

Each of these steps is crucial for fostering an optimal environment for fermentation, ultimately leading to the best possible results in your brewing process, ensuring healthy yeast cells and proper ethanol production.

1. Adjusting Temperature

Adjusting fermentation temperature can have a profound impact on yeast metabolism and overall fermentation activity, effectively addressing issues like stuck fermentation and ensuring smooth transitions through different fermentation phases.

By fine-tuning the temperature within specific ranges, you can create an optimal environment that fosters robust yeast growth and enhances the production of desirable fermentation characteristics.

For example, warmer temperatures can invigorate yeast activity during the early stages, resulting in a quicker alcohol fermentation process, while cooler conditions help preserve the delicate esters and phenols that contribute to intriguing flavor complexity.

Utilizing techniques such as heat exchange systems or insulated fermenters allows you to manage these temperature variations expertly. This intentional manipulation can lead to improved yeast performance, minimized off-flavors, and ultimately, a refined final product that aligns perfectly with your brewing aspirations.

Proper fermentation temperature control is essential for achieving high-quality results in your homebrewing endeavors!

2. Adding Nutrients and Monitoring Yeast Health

Adding nutrients to fermentation is crucial for yeast growth and health, particularly with high gravity worts and ale yeast. These yeast nutrient supplements supply essential building blocks that yeast needs to flourish and convert sugars into alcohol effectively.

Without sufficient nutrients, yeast metabolism may slow down or even halt, leaving unfermented sugars that can lead to off-flavors. Breweries typically introduce these nutrients at various fermentation stages usually at the onset and sometimes during progression to maintain consistent yeast vitality.

By providing the right nutrient balance, you support the yeast for a vigorous fermentation, ultimately crafting higher quality beer with desirable flavor profiles. Ensuring optimal fermentation conditions is key for robust yeast reproduction and activity.

3. Sanitizing Equipment

Sanitizing your equipment is essential for preventing infections that could ruin a batch of beer and compromise yeast health. To meet the highest quality standards, every step from brewing to bottling requires meticulous attention to cleanliness.

Implementing effective sanitation practices, such as thoroughly cleaning fermentation vessels and using chlorinated cleaners, is crucial for maintaining the integrity of your brewing process. Focus on areas where bacteria thrive; doing so can save your brew from unwanted flavors and aromas that affect your beer’s overall profile.

By employing techniques like steam cleaning and utilizing specialized sanitizers, you can safeguard your investment, ensuring flavors are preserved and fermentation remains robust without the nagging worry of contamination.

Frequently Asked Questions

What is the fermentation timeline for brewing?

The fermentation timeline for brewing varies depending on the beer type and specific recipe. On average, fermentation can take one to three weeks, including primary fermentation and potentially secondary fermentation for certain beer styles.

What happens during the first few days of fermentation?

During the first few days, yeast consumes sugars in the wort, converting them into alcohol and CO2. This period showcases the most activity in your fermenter, known as krausen formation, with bubbles and foam appearing on the surface.

What is the expected gravity drop during fermentation?

The expected gravity drop during fermentation is typically around 50-70%. This means that the original specific gravity of the wort drops by about half to two-thirds as the sugars are converted into alcohol.

What is the purpose of secondary fermentation?

Secondary fermentation is an optional step used for high gravity beers or when adding additional ingredients like fruits or spices. It allows for further fermentation and conditioning, resulting in a smoother, more complex flavor. This phase is crucial for achieving quality in Belgian tripels and other complex beer styles.

What can cause a longer fermentation time?

A longer fermentation time can arise from several factors, such as using lower quality yeast, insufficient oxygen in the wort, or fermenting at too low a temperature. Properly preparing and monitoring fermentation is vital for a timely and successful brew. Poor yeast health can also contribute to prolonged fermentation.

How can I tell when fermentation is complete?

The best way to determine when fermentation is complete is by taking gravity readings with a hydrometer. If the gravity remains stable for a few consecutive days, fermentation is likely complete. Tasting the beer can also help determine if it has reached the desired flavor profile. Monitoring fermentation activity and visual cues are key indicators of completion.