Fermentation: Key to Craft Beer Success

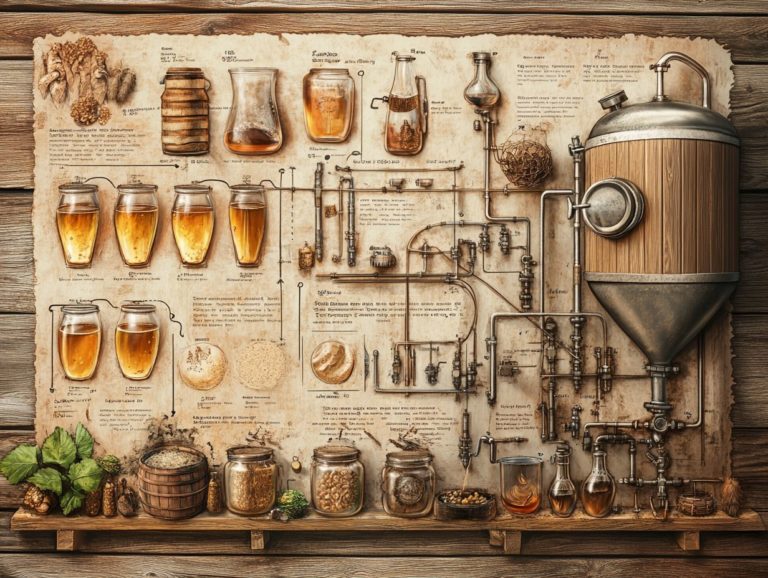

Fermentation is the core of craft beer production, transforming simple ingredients into a symphony of complex flavors and distinctive brews. This intricate brewing process not only sets craft beer apart from its commercial counterparts but also plays a crucial role in enhancing its taste and aroma.

Dive into the captivating world of fermentation! Discover how it shapes craft brewing, including the role of fermentation aids and effective fermentations.

Contents

- Key Takeaways:

- What is Fermentation?

- The Role of Fermentation in Craft Beer

- The Importance of Yeast in Fermentation

- Types of Yeast in Craft Beer

- How Does Yeast Affect the Flavor and Aroma of Craft Beer?

- The Fermentation Process in Craft Beer Production

- Common Issues and Challenges in Fermentation

- What Are the Most Common Issues Encountered During Fermentation?

- The Future of Fermentation in Craft Beer

- Frequently Asked Questions

- What is fermentation and why is it important for craft beer success?

- What types of yeast are commonly used in craft beer fermentation?

- How does temperature affect the fermentation process?

- Why Are Hops Essential in Craft Beer Brewing?

- What Risks Does Fermentation Present in Craft Beer Brewing?

- How Long Does Fermentation Take in Craft Beer Brewing?

Key Takeaways:

- Fermentation is a crucial step in craft beer production, responsible for creating unique flavors and aromas.

- Yeast health and vitality are essential for achieving effective fermentations.

- The type of yeast used in fermentation plays a significant role in the final taste and aroma of craft beer.

- Ongoing advancements in fermentation technology will continue to shape and enhance the craft beer industry in the future.

What is Fermentation?

Have you ever wondered how simple ingredients transform into the rich flavors of craft beer? That s the magic of fermentation! It is an essential biochemical process in which microorganisms, predominantly yeast, transform sugars into alcohol and carbon dioxide. This remarkable process is vital in many areas, including food preservation and brewing.

Notable figures such as Louis Pasteur and Emil Hansen paved the way for our understanding of fermentation. Within the brewing community, fermentation takes the wort, which is the liquid extracted from malted grains, crafted from malted barley and hops, and turns it into unique craft beers. This practice stretches back to ancient civilizations and reveals the fascinating fermentation mysteries.

Fermentation not only drives alcohol production but also significantly enhances the flavors and aromas of the final product, elevating your tasting experience to new heights.

How Does Fermentation Work?

The fermentation process unfolds through the remarkable metabolic activity of yeast, particularly a type of yeast called Saccharomyces cerevisiae. This yeast flourishes under optimal fermentation conditions, including the ideal temperature and proper nitrogen requirements.

This extraordinary organism consumes sugars, transforming them into alcohol and carbon dioxide via a series of intricate enzymatic reactions. You start by pitching yeast into the fermenting medium, igniting the fermentation journey and monitoring fermentation stages.

As this process progresses, you will notice krausen formation a foamy layer on the surface that signifies active fermentation. At this pivotal stage, it s essential to maintain the vitality and health of the yeast through proper yeast nutrients. Robust yeast cells can efficiently ferment sugars, resulting in a cleaner and more effective fermentation.

If the conditions aren t right and the yeast isn t viable, you risk stalling the fermentation or introducing off-flavors, which can jeopardize the desired outcome of your beverage.

The Role of Fermentation in Craft Beer

Fermentation is an essential cornerstone in the world of craft beer production, shaping everything from the alcohol content to the complex flavors that distinguish different styles. Unlike commercial beer, craft beer prioritizes distinctive fermentation processes and innovative brewing techniques that truly reflect the artistry of the brewers.

Brewers like Chris White from White Labs and Julian Shrago from Beachwood Brewing have made significant contributions to this field. By employing a variety of fermentation aids and yeast strains, craft brewers create a remarkable array of characteristics, inviting you to delve into the rich complexities of beer production and discover new dimensions of flavor.

Brewers like Garrison Fratoni from Russian River experiment with various yeast strains to achieve unique results.

What Makes Craft Beer Different from Commercial Beer?

Craft beer sets itself apart from commercial beer primarily by prioritizing quality, flavor, and traditional brewing methods. You ll often find unique fermentation processes at play that truly showcase the brewer’s artistry. Historical brewing equipment like the Burton Union system and Yorkshire squares have also contributed to the distinctiveness of craft beer.

These remarkable characteristics arise from the use of high-quality ingredients, often sourced locally or even grown by the brewers themselves, contributing to an unparalleled depth of flavor. While commercial beer is produced on a grand scale, yielding a more uniform taste designed to please the masses, craft beer presents an abundance of styles and flavors that cater to a diverse array of palates.

Innovative brewing techniques enable craft brewers to experiment with unconventional ingredients, resulting in seasonal or limited-edition brews that cultivate a vibrant sense of community among enthusiasts. This dynamic interaction invites you to explore, learn, and support your local breweries, ultimately enriching the overall beer culture. Successful craft breweries like Russian River and Beachwood Brewing exemplify this vibrant community.

How Does Fermentation Affect the Flavor of Craft Beer?

Fermentation profoundly impacts the flavor profile of craft beer, where various yeast strains and fermentation temperatures come together to create distinct characteristics ranging from fruity esters to spicy phenols. Proper wort preparation and maintaining ideal fermentation conditions are crucial in achieving these desirable traits.

The health of your yeast is crucial in determining the overall quality of your beer; stressed yeast can introduce off-flavors and undesirable compounds that may stray far from your intended brew. The choice of fermentation vessels, whether you opt for open fermenters or closed tanks, creates variable environments that influence oxygen exposure and temperature regulation. Additionally, stages like the diacetyl rest ensure cleaner flavors by allowing the yeast to reabsorb unwanted byproducts.

As the yeast consumes sugars and releases byproducts, a series of biochemical reactions unfolds, not only affecting flavor but also enhancing aroma, adding layers of complexity that every artisan aims to achieve in their craft. By understanding these elements, you can tailor your brewing processes, ultimately crafting unique and enjoyable beverages that truly reflect your creative vision.

What Are the Different Types of Fermentation Used in Craft Beer?

Craft beer utilizes a variety of fermentation techniques, including primary fermentation, secondary fermentation, and lager brewing, each adding unique characteristics to the final creation. The terminal gravity measured at the end of fermentation helps to determine the beer’s final alcohol content.

Every fermentation method significantly influences the flavors and aromas that define distinct beer styles. Top fermentation, predominantly employed for ales, occurs at warmer temperatures, allowing yeast to flourish and infuse a delightful array of fruity and complex notes. On the other hand, bottom fermentation typical for lagers takes place under cooler conditions, yielding cleaner, crisper flavors with a more restrained ester profile.

By grasping the subtleties of these processes, you not only enable brewers to manage the brewing timeline effectively but also enhance their capacity to craft beers that appeal to a diverse range of tastes and preferences. This knowledge, coupled with an understanding of yeast pitching and fermentation efficiency, contributes to the vibrant tapestry of craft beer culture, allowing aficionados like you to truly appreciate the art and science behind each brew.

The Importance of Yeast in Fermentation

Yeast serves as the cornerstone of the fermentation process, acting as the catalyst that transforms sugars into alcohol and carbon dioxide, while also shaping the flavor profile of the beer.

The health and vitality of yeast strains are crucial in the brewing world; they are fundamental to achieving effective fermentations. This makes the use of yeast nutrients and the correct pitching of yeast essential elements for successful brewing. Yeast growth and protein breakdown are key factors in maintaining yeast vitality.

Types of Yeast in Craft Beer

As you delve into the world of craft beer brewing, you’ll discover a plethora of yeast strains, with Saccharomyces cerevisiae reigning supreme for ales. Lager yeasts are expertly employed to achieve that crisp, clean taste you love.

Beyond these familiar varieties, a myriad of other yeast options beckons. Each one bestows its unique flavors and aromas upon the final brew. For example, Brettanomyces, known for its funky and earthy notes, finds a place of honor in certain sour and wild ales, contributing layers of complexity and depth that evolve beautifully over time.

On the other hand, strains like Saccharomyces pastorianus are the secret weapon behind lagers. They ensure a smoother fermentation journey and amplify that refreshing crispness. These different strains contribute to the rich history of brewing techniques.

Your choice of yeast is paramount in defining the beer’s character. Each strain dances to its own tune when it comes to sugars, temperatures, and oxygen levels, ultimately shaping the aroma, taste, and mouthfeel you experience. Therefore, selecting the right yeast isn t just a minor detail it s a pivotal decision that crafts the very identity of your beer.

How Does Yeast Affect the Flavor and Aroma of Craft Beer?

Yeast plays a pivotal role in shaping the flavor and aroma of your craft beer. Its by-products created during fermentation introduce a delightful array of esters (fruity flavors) and phenols (spicy flavors) that contribute to the beer’s sensory experience. You must monitor fermentation temperature to manage these by-products.

As yeast metabolizes sugars, it forms compounds that are crucial in defining your beer’s character. For example, certain yeast strains can produce fruity esters like isoamyl acetate, imparting those enticing banana or pear notes, while others may generate spicy phenols, reminiscent of clove or pepper. Understanding brewing biology can elevate your craft to new heights!

Maintaining the health of your yeast is essential. Stressed or unhealthy yeast can lead to off-flavors and undesirable aromas that compromise your brewing intentions. By ensuring optimal fermentation conditions such as the right temperature and nutrient availability you can promote vigorous yeast activity.

This enhances the complexity and richness of your final product, resulting in a beer that is both balanced and irresistibly appealing to the senses. Utilizing fermentation aids can further ensure the effective fermentations you desire.

The Fermentation Process in Craft Beer Production

The history of brewing is rich with traditions and innovations that have shaped the modern brewing process. From ancient societies to today’s craft breweries, fermentation remains a fundamental aspect of beer production.

The fermentation process in craft beer production unfolds through several essential stages. It all begins with primary fermentation, where yeast diligently transforms the sugars in the wort into alcohol and carbon dioxide. This is followed by secondary fermentation, a stage that meticulously refines the flavors and aromas of the beer, enhancing its overall character and complexity.

Understanding these stages can help demystify some of the fermentation mysteries that have intrigued brewers for generations.

What Are the Key Steps in the Fermentation Process?

The key steps in the fermentation process include:

- wort preparation

- pitching your yeast

- overseeing primary fermentation

- monitoring its progress

- measuring terminal gravity to know when fermentation has reached completion.

Each of these elements is vital for ensuring a successful outcome, whether you re crafting beer, wine, or any other fermented product. After you carefully pitch the yeast, the catalyst for fermentation, it is crucial to maintain optimal temperature and pH levels, as these factors significantly affect yeast activity and the fermentation process as a whole.

Proper yeast nutrients should also be considered to meet the nitrogen requirements of the yeast. By regularly taking measurements, such as specific gravity readings during the primary fermentation phase, you can effectively gauge how efficiently the yeast is converting sugars into alcohol.

When the terminal gravity stabilizes over a few days, it clearly indicates that fermentation is complete, giving you the confidence to move on to the next steps of the process, such as conditioning or bottling. Including a diacetyl rest at the end of primary fermentation can help remove unwanted compounds.

How Long Does the Fermentation Process Take?

The duration of the fermentation process can vary significantly for you, influenced by several factors, including the type of beer you re brewing, the fermentation temperature, and whether you choose to engage in primary or secondary fermentation. Proper yeast management, including understanding the nitrogen requirements and protein breakdown, is essential for effective fermentation.

Typically, primary fermentation lasts anywhere from one to three weeks as the yeast works diligently, consuming sugars and producing alcohol. Keep in mind that temperature is crucial. Higher temperatures can speed up fermentation, while cooler ones might extend it. The type of fermentation vessels used can also influence the duration and quality of fermentation.

After the initial phase, secondary fermentation may take a few days to several weeks. This phase provides an opportunity for your brew to clarify and develop complex flavors.

Your brewing techniques can dramatically affect fermentation length. Don t underestimate the impact of your choices! Incorporating dry hopping or adding adjuncts can also affect fermentation length, as the yeast may take more time to process those additional ingredients. Ultimately, the yeast strain you select will play a pivotal role in the overall timeline, with some strains working faster than others. Notable figures in the brewing community, such as Chris White of White Labs and Julian Shrago of Beachwood Brewing, have contributed significantly to our understanding of yeast strains and effective fermentation.

Common Issues and Challenges in Fermentation

Fermentation can pose a range of challenges and common issues that you may encounter, including stuck fermentations, undesirable off-flavors like diacetyl, and concerns regarding yeast health and vitality.

Each of these factors can profoundly influence the overall quality of your craft beer.

What Are the Most Common Issues Encountered During Fermentation?

You may encounter several common issues during fermentation, such as stuck fermentation, where yeast activity grinds to a halt prematurely, or the production of diacetyl, which can introduce off-flavors that compromise the quality of your beer. Yeast health is paramount to avoiding these issues.

Factors like improper temperature control, inadequate oxygen levels, and nutrient deficiencies can contribute to these fermentation challenges.

Stuck fermentation often happens with high gravity worts that put stress on the yeast. Diacetyl is typically produced as a byproduct of yeast under stress due to temperature fluctuations or insufficient pitching rates. Using proper fermentation monitoring tools can help in the early detection of such issues.

Employing monitoring techniques like regular gravity checks, assessing yeast health, and logging temperature data is essential for identifying these issues promptly. By making necessary adjustments whether that means regulating fermentation temperatures or adding nutrient supplements you can maintain yeast activity and ensure the overall quality of your beer, resulting in a final product that is both enjoyable and consistent.

How Can These Issues Be Prevented or Resolved?

Preventing and resolving fermentation issues is within your reach through meticulous monitoring of fermentation conditions, ensuring yeast health, and implementing the best brewing techniques for a successful fermentation process.

As a brewer, you should focus on several proactive measures to achieve optimal results. Effective yeast management is fundamental. This entails pitching the right amount of healthy yeast and providing adequate aeration to promote vigorous fermentation.

Controlling fermentation temperatures is essential because fluctuations can lead to undesirable byproducts or stalled fermentation.

By employing precise monitoring techniques such as hydrometers or refractometers you can track gravity changes and swiftly identify when fermentation is lagging.

If you encounter common issues like stuck fermentation or off-flavors, tackle these challenges by adjusting the temperature, repitching yeast, or using fining agents to clarify the brew and elevate its flavors. Understanding the role of yeast vitality and fermentation efficiency can also aid in resolving these challenges.

The Future of Fermentation in Craft Beer

The future of fermentation in craft beer is exceptionally promising, as cutting-edge fermentation technologies and advancements in brewing techniques continue to unfold. Pioneers like Emil Hansen of Carlsberg Laboratories and Louis Pasteur have laid the groundwork for these exciting developments.

This evolution enables you to explore new flavors and refine your brewing process, opening up a world of possibilities for your craft.

What Innovations and Advancements Are Being Made in Fermentation Technology?

Innovations in fermentation technology, such as advanced fermentation monitoring systems and yeast management tools, are transforming your craft beer experience. They enable you to produce high-quality brews with remarkable consistency and efficiency.

These advancements allow you to automate various brewing processes. This gives you the ability to meticulously control critical variables like temperature, pressure, and oxygen levels with unparalleled precision. Data analytics becomes your ally in interpreting the processes involved in fermentation, providing you with valuable insights into yeast behavior and fermentation kinetics. Utilizing advanced brewing equipment like hydrometers or refractometers aids in achieving such precision.

The introduction of sophisticated fermentation vessels featuring innovative designs that improve oxygen transfer and temperature stability further optimizes your brewing process. Local breweries are increasingly adopting these technologies, enhancing the quality of their craft beers and enriching the overall experience for their customers.

How Will Fermentation Continue to Shape the Craft Beer Industry?

Fermentation will continue to shape your experience in the craft beer industry, driving trends towards unique flavor profiles and innovative brewing practices. This fosters a culture of experimentation and creativity among brewers that you ll find exhilarating!

As brewers embrace diverse fermentation techniques, they delve into ingredients from unusual sources, crafting a rich tapestry of tastes that will delight your adventurous palate. This ongoing experimentation not only sets individual breweries apart but also leads to exciting collaborations and limited-edition releases that beckon you to seek out new experiences. Expect to see more use of indigenous yeasts and sustainable practices in the brewing process.

As the industry evolves, you’ll notice a growing emphasis on sustainability and local sourcing influencing fermentation methods. Expect the incorporation of indigenous yeasts and eco-friendly practices that resonate with your values. Such developments paint a promising landscape where fermentation remains at the core of craft beer’s identity, ensuring its evolution captivates you for years to come. Breweries like Russian River and Beachwood Brewing are at the forefront of these sustainable practices.

Frequently Asked Questions

What is fermentation and why is it important for craft beer success?

Fermentation is the process in which yeast converts sugars into alcohol and carbon dioxide, resulting in the delicious beverage we know as beer. It is a crucial step in the brewing process as it not only produces alcohol but also adds flavor and character to the beer. This process has been honed over centuries, with ancient societies utilizing microbial fermentation for beer production.

What types of yeast are commonly used in craft beer fermentation?

Ale yeast and lager yeast are the two main types of yeast used in craft beer fermentation. Ale yeast is known for producing fruity and complex flavors, while lager yeast creates a clean and crisp taste. Saccharomyces cerevisiae is commonly used in ale fermentation, while Saccharomyces pastorianus is used in lager brewing.

How does temperature affect the fermentation process?

The temperature at which fermentation takes place greatly impacts the final product. Higher temperatures result in a faster fermentation process but can also produce off-flavors and harshness in the beer. Lower temperatures result in a slower process, which can create a smoother and more refined taste. Fermentation temperature is a critical factor in beer production and impacts yeast health during fermentation.

Why Are Hops Essential in Craft Beer Brewing?

Hops are a vital ingredient in brewing. They balance the sweetness of malt and add delightful aromas and flavors.

During fermentation, hops also act as a natural preservative, preventing unwanted bacteria growth. They influence all fermentation stages, including primary and secondary.

What Risks Does Fermentation Present in Craft Beer Brewing?

Fermentation is thrilling but comes with risks that every brewer must tackle! If fermentation isn t properly controlled, it can lead to unpleasant flavors or spoilage of the beer.

If equipment used in fermentation isn t sanitized properly, it can introduce unwanted bacteria. Effective fermentation methods, proper yeast management, and close monitoring are crucial for success!

How Long Does Fermentation Take in Craft Beer Brewing?

The length of fermentation varies based on the beer type, yeast, and desired flavors. Typically, fermentation can take from a few days to several weeks.

Some craft breweries might let their beers ferment for even longer to achieve a complex and refined taste. Factors like yeast health and fermentation aids also influence the duration and quality.