How to Optimize Your Fermentation Conditions

Fermentation is a remarkable process that transforms simple ingredients into a world of complex flavors, significant health benefits, and valuable compounds.

Whether you’re a passionate home cook, an aspiring brewer, or simply intrigued by this culinary technique, understanding fermentation can greatly enhance your dishes and contribute to your overall well-being.

In this article, you will discover the numerous benefits of fermentation, essential factors for its success, practical tips for optimization, common pitfalls to avoid, and effective troubleshooting strategies.

Get ready to discover the exciting secrets of fermentation, including yeast and microbial fermentation, and elevate your culinary journey!

Contents

- Key Takeaways:

- Why is Fermentation Important?

- What Factors Affect Fermentation?

- How to Optimize Fermentation Conditions?

- 1. Monitor and Control Temperature

- 2. Adjust pH Levels

- 3. Control Oxygen Levels

- 4. Provide Adequate Nutrients

- What Are the Common Mistakes in Fermentation?

- Fermentation Troubleshooting Guide

Key Takeaways:

- Monitor and control temperature to optimize fermentation conditions for better results, ensuring efficient microbial activity and robust biomass production.

- Adjust pH levels and provide adequate nutrients, such as carbon and nitrogen sources, to create a favorable fermentation environment.

- Avoid common mistakes, such as using non-sterile equipment and neglecting to track bacterial growth, to improve fermentation outcomes.

Why is Fermentation Important?

Fermentation is a key technology that converts natural materials into valuable products through the power of microbial action. This process is essential across various industries, from food and beverage to pharmaceuticals and bioengineering.

Not only does fermentation enhance the nutritional profile of food, but it also produces important compounds like alcohols, acids, and gases, which are crucial for many industrial applications. Moreover, fermentation technology optimizes biomass production while ensuring efficiency, solidifying its role in modern processing strategies.

What Are the Benefits of Fermentation?

Fermentation offers a wealth of advantages that enhance both the quality and safety of food products. This leads to improved yields and minimizes off-flavors that can arise from poorly managed processes or contamination.

By optimizing your fermentation conditions such as managing nutrient requirements, temperature, and metabolic pathways you can achieve a more reliable and efficient fermentation process. These advantages elevate the sensory qualities of your products while boosting their nutritional value and shelf life, ensuring consumer satisfaction.

The fermentation process enriches flavors, creating complex taste profiles that are highly sought after. Improved digestibility of nutrients allows consumers to absorb vitamins and minerals more effectively, promoting better health overall.

Methods like biomass monitoring during fermentation help maintain precise control over microbial activity, resulting in superior product consistency and safety. This optimization prevents spoilage, extends shelf life, and reduces waste, turning fermentation into a culinary art that aligns with contemporary dietary preferences. For example, real-time data and fermentation parameters can be adjusted to ensure high quality.

What Factors Affect Fermentation?

Several critical factors influence the fermentation process, significantly impacting the growth curves of microorganisms and the overall efficiency of microbial fermentation. Temperature is one of these key factors that requires careful control. It optimizes metabolic activity and ensures consistent fermentation quality throughout the different phases: lag phase, acceleration phase, log phase, deceleration phase, stationary phase, and death phase.

pH levels play a crucial role in determining the acidity of the fermentation medium. Additionally, oxygen levels are essential for aerobic fermentation, influencing the dynamics of the process and aiding in efficient fermentation yields.

Furthermore, nutrient availability is vital as it supports microbial growth and drives fermentation dynamics. This ultimately affects the quality and yield of the final product. Both the nitrogen and carbon sources must be optimized to meet nutritional requirements.

1. Temperature

Temperature plays a crucial role in fermentation. It directly impacts the metabolic activity of microorganisms and their growth conditions. Each type of fermentation whether with yeast or bacteria has its own optimal temperature range that maximizes how well the microorganisms work and biomass production.

Effective temperature management is a critical aspect of fermentation design. Variations in temperature can profoundly affect the fermentation process at different growth phases. For instance, during the lag phase, microorganisms may need additional time to adjust to temperature changes, potentially delaying the start of fermentation.

As you move into the log phase, maintaining optimal temperatures fosters vigorous growth and rapid reproduction. Fluctuations can hamper cellular activity and lead to uneven fermentation.

In the stationary phase, improper temperature management can increase cell death rates. This creates off-flavors and raises the risk of contamination. Precise temperature control is crucial for successful fermentation and can make or break your product!

2. pH Level

The pH level of your fermentation medium is critical for achieving peak performance from your microorganisms. It significantly influences enzyme activity and metabolic processes. By managing pH properly, you can ensure that microbial fermentation runs smoothly, enhancing your fermentation yield and preventing the formation of unwanted byproducts.

To achieve optimal pH management, automated sampling and continuous measurement of pH levels are recommended. Maintaining the correct pH range promotes the growth of desirable strains and keeps spoilage organisms at bay. This is vital for preserving the quality of your final product.

When pH levels stray too high or too low, fermentation efficiency wanes, leading to sluggish rates and reduced yields. Extreme fluctuations can compromise the flavor, aroma, and color of your creations, whether it’s wine, beer, or yogurt.

Continuous monitoring and adjusting of pH levels during the fermentation process are critical practices, whether you’re brewing on an industrial scale or experimenting at home. This vigilance ensures that your final product meets the high standards of quality and consistency you aim for.

3. Oxygen Levels

Oxygen levels in the fermentation medium are important in shaping the fermentation process, particularly in aerobic fermentation. The presence of oxygen is vital for optimal microbial growth (the increase of microorganisms) and metabolite production (substances produced during metabolism).

By carefully balancing these oxygen levels, you can ensure efficient fermentation. This practice leads to enhanced fermentation yields and effective biomass monitoring. Oxygen management is thus a critical practice in fermentation science.

When oxygen is limited or absent, you enter the realm of anaerobic fermentation. In this scenario, microorganisms like yeast and specific bacteria shift to alternative substrates for energy production.

This shift not only produces different end products such as ethanol or lactic acid but also impacts energy efficiency and biomass accumulation. Grasping these dynamics unlocks the potential for optimizing bioreactor efficiency.

Understanding these distinct fermentation processes is essential for industries like brewing and biofuel production. The conditions you choose whether aerobic or anaerobic directly influence flavor profiles, shelf-life, and the overall quality of the final products.

Ultimately, understanding the implications of oxygen levels empowers you to take better control and optimize your fermentation strategies for superior outcomes with the help of advanced bioprocessing technologies.

4. Nutrient Availability

Nutrient availability is a crucial element of fermentation that directly influences microbial growth and the outcomes you can expect. It provides the essential components necessary for cell division and metabolic activities.

To achieve high fermentation efficiency and yield, optimizing nutrient sources within your fermentation medium such as carbon and nitrogen is vital. Detailed nutrient management and medium optimization are essential for ensuring the effectiveness of the fermentation process.

This optimization requires you to carefully balance the concentrations of various nutrients, including vitamins, minerals, and trace elements. This balance fosters an environment that encourages the desired microbial activity.

Different fermentation processes may demand specific nutrient profiles, which can significantly affect the dynamics of microbial populations and their metabolic pathways.

Tools like high-resolution data from manual sampling and automated sampling can aid in maintaining appropriate nutrient levels. For instance, when producing biofuels or pharmaceuticals, the right nutrient composition can enhance the growth rates of beneficial microorganisms while suppressing the unwanted ones.

Therefore, a comprehensive understanding of nutrient requirements and their interactions in the fermentation medium is essential for maximizing both the performance of your fermentation process and the quality of the final products.

Companies like Fermentis, ABPDU, and TeselaGen offer advanced solutions for optimizing nutrient profiles in fermentation processes.

How to Optimize Fermentation Conditions?

Optimizing fermentation conditions is crucial for enhancing both the efficiency and yield of microbial fermentation processes. This involves a careful and detailed approach to monitoring and controlling various parameters, including temperature management, oxygen management, and pitching rate.

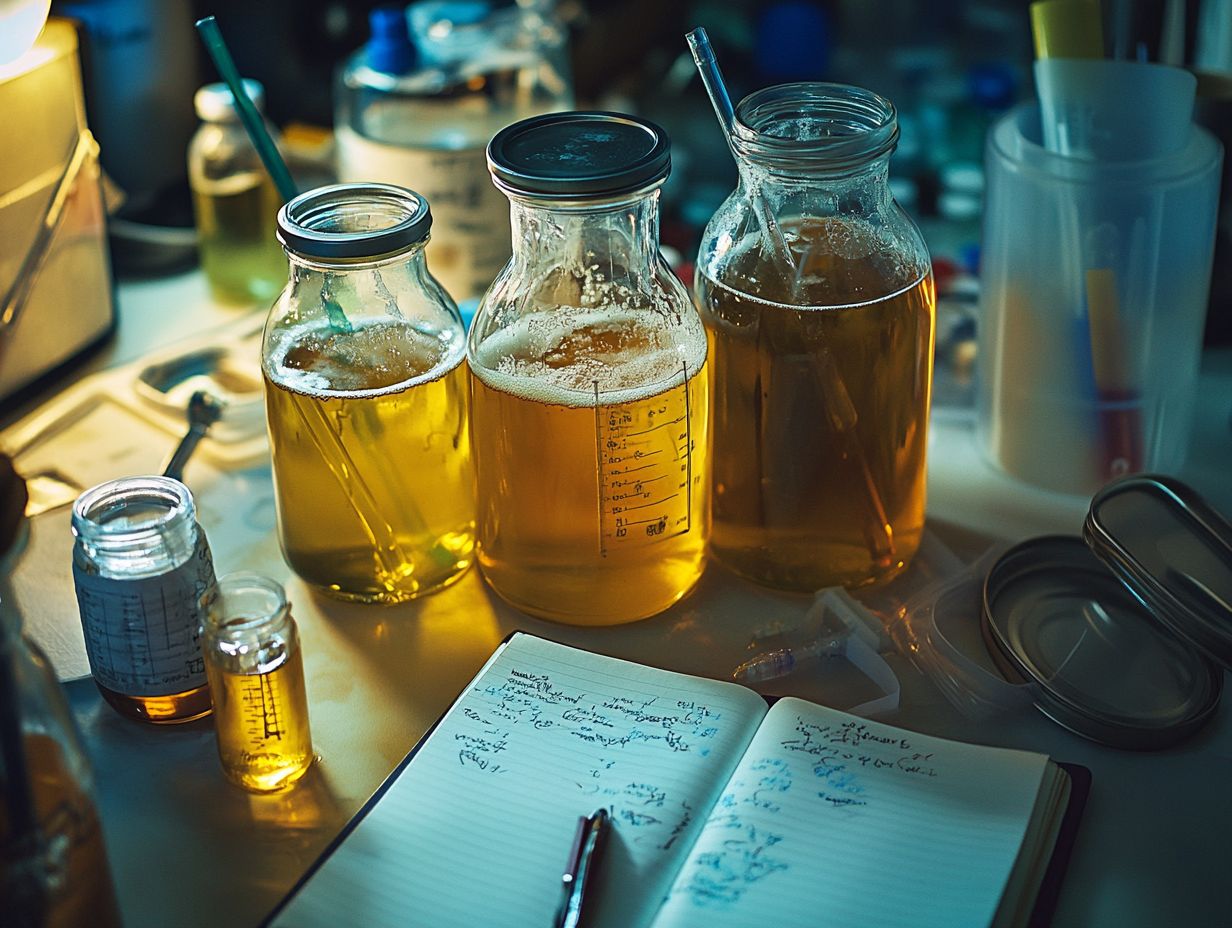

By utilizing techniques such as online biomass monitoring, you can gather real-time data to refine key aspects like temperature, pH levels, and nutrient management. This meticulous attention ensures that the fermentation process remains within optimal conditions at every stage.

Advanced bioreactor systems equipped with continuous measurement and contamination detection capabilities further enhance the reliability and efficiency of microbial fermentation.

What strategies will you implement to enhance your fermentation results today?

1. Monitor and Control Temperature

Monitoring and controlling temperature during fermentation is essential for ensuring that microbial processes work well. This significantly enhances bioprocessing technologies, such as biomass monitoring and fermentation yield.

Precise temperature control can significantly enhance fermentation. Implementing effective temperature management creates optimal growth conditions throughout all phases, including the lag phase and log phase.

Utilizing advanced bioreactor systems with sophisticated temperature sensors allows you to maintain specific thermal conditions during fermentation. These systems adjust temperature levels based on real-time data, ensuring an ideal environment for microbial activity.

Keeping the right temperatures is crucial for maximizing your fermentation success. This not only improves metabolic efficiency but also influences product quality and consistency.

Integrating effective temperature management strategies will significantly enhance your fermentation success. This results in higher yields and improved performance across various biotechnology applications, including the production of insulin and HPV vaccines.

2. Adjust pH Levels

Adjusting pH levels in your fermentation medium is crucial for optimizing microbial fermentation. It significantly influences enzyme activity and metabolic processes.

By regularly monitoring and making timely adjustments, you can prevent issues such as off-flavors. This ensures that the fermentation process remains within the desired range.

Effective oxygen management also plays a critical role in maintaining suitable conditions.

To effectively adjust pH, consider using buffering agents that stabilize pH fluctuations during fermentation. Advanced monitoring systems are invaluable, allowing you to track pH levels in real-time.

The impact of pH on fermentation parameters such as yeast viability, metabolism, and product characteristics is profound. Even minor deviations can affect the final quality of products like beer and wine.

Proper pH management fosters a healthy fermentation environment. It also enhances the sensory attributes of your final products, contributing to overall fermentation optimization.

3. Control Oxygen Levels

Controlling oxygen levels is essential in your fermentation processes, especially during aerobic fermentation. The right amount of oxygen can significantly boost microbial growth and metabolite production.

Establish precise oxygen control to optimize your fermentation environment. This ensures efficient biomass production while minimizing undesirable off-flavors through advanced oxygen management techniques.

You might consider employing aeration techniques like sparging and surface aeration to effectively adjust oxygen levels. Utilizing bioreactor systems with automated monitoring capabilities for continuous measurement will allow real-time adjustments.

Maintaining appropriate oxygen levels supports the health and growth of your microorganisms. This plays a critical role in achieving your desired fermentation outcomes, including yield and quality.

Incorporating aeration strategies and advanced bioreactor designs ensures a balanced and productive fermentation process. This ultimately leads to greater success in various applications, including the production of cancer antibodies.

4. Provide Adequate Nutrients

Providing adequate nutrients is essential for fermentation success. It ensures that microorganisms have the necessary building blocks for growth and substance production.

By carefully managing nutrient sources, including carbon and nitrogen sources, you can optimize fermentation conditions and significantly enhance overall process efficiency. This is a crucial aspect of nutrient requirements management.

Other critical nutrients also play a pivotal role in supporting the metabolic pathways involved in fermentation. For example, optimizing phosphorus and potassium levels can lead to improved biomass yields and product formation.

Effective nutrient medium optimization can boost overall fermentation efficiency. To manage nutrients effectively, consider implementing strategies such as pre-fermentation nutrient profiling and real-time monitoring of nutrient concentrations.

This allows you to make timely adjustments based on the specific demands of the fermentation phase, enhancing fermentation optimization. Understanding the relationship between nutrient availability and fermentation outcomes is crucial.

Imbalances can lead to less-than-ideal results, such as slower fermentation rates or the production of undesirable byproducts. Proper planning for the fermentation process helps in achieving optimal outcomes.

What Are the Common Mistakes in Fermentation?

Common mistakes in fermentation can seriously impact the efficiency and yield of microbial fermentation processes. These often arise from inadequate monitoring and a failure to optimize conditions.

Effective fermentation design and fermentation science practices are essential to avoid such errors. Address these errors to enhance your fermentation outcomes, as even the smallest oversights can result in significant issues.

These issues may include contamination, off-flavors, and diminished metabolite production. By paying attention to these details, you can elevate your fermentation process and achieve the desired results.

1. Not Using Sterile Equipment

Neglecting to use sterile equipment during fermentation can lead to contamination. This undermines the entire microbial fermentation process and introduces unwanted byproducts or off-flavors.

It is crucial to ensure that all equipment is properly sterilized to maintain the integrity of the fermentation environment. This is critical in bioengineering techniques to maintain high standards.

This aspect is especially vital in industries such as brewing, winemaking, and dairy production. Harmful microorganisms can spoil your product and pose health risks to consumers.

Contamination can generate undesired flavors and aromas that significantly detract from the intended profile of your beverage or food item. Frequent contamination detection is therefore necessary.

Implementing effective sterilization practices, whether through heat treatment or chemical sanitization, is essential for ensuring that your fermentation process is efficient and yields high-quality results.

By carefully monitoring your sterilization protocols, you can greatly reduce the risk of spoilage. This ultimately enhances both consumer satisfaction and product safety. Companies like Fermentis offer solutions for effective sterilization practices.

Fermentation Troubleshooting Guide

2. Not Monitoring Fermentation Progress

Neglecting to monitor fermentation progress can lead to significant setbacks in the process. You might miss crucial opportunities to adjust conditions based on real-time data. Continuous online biomass monitoring is essential for ensuring that your fermentation remains within optimal parameters throughout its various phases, including the lag phase and log phase.

This proactive approach safeguards the quality of your final product and minimizes the risk of developing off-flavors that could compromise the integrity of the beverage or food item you are producing. Implementing a process strategy helps maintain quality.

By employing advanced techniques such as in-line sensors, spectrophotometry, and gas chromatography, you gain access to precise, real-time insights into fermentation dynamics. Companies like ABPDU and TeselaGen provide these advanced tools for better biomass monitoring.

Analyzing parameters like pH, temperature, and specific gravity allows you to achieve efficient fermentation, enhancing overall yield and reducing resource wastage. Keeping a close watch on these details ensures you get the best results!

3. Not Adjusting for Optimal Conditions

Failing to adjust fermentation conditions for optimal performance can lead to disappointing results, stunting microbial growth and metabolite production. By understanding the various growth curves and phases of fermentation, such as the lag phase, acceleration phase, log phase, deceleration phase, stationary phase, and death phase, you can make informed adjustments to enhance your fermentation process.

Recognizing these phases involves understanding the lag phase, during which cells acclimatize to their environment; the log phase, marked by rapid population growth; and the stationary phase, when resources start to run low. Each of these stages comes with specific requirements regarding temperature, pH, and nutrient availability. Tailoring your interventions during these crucial periods boosts fermentation efficiency and elevates the overall quality of your final product. Effective fermentation technology implementation is key.

For example, maintaining optimal oxygen levels can significantly increase yields of desirable metabolites. Closely monitoring nutrient concentrations ensures that microbial activity remains robust throughout the fermentation process. Advanced bioprocessing technologies facilitate this.

How to Troubleshoot Fermentation Problems?

Troubleshooting fermentation problems demands a systematic approach that enables you to identify and rectify any issues during microbial fermentation, such as contamination, off-flavors, or suboptimal yields. By thoroughly analyzing fermentation parameters and conditions, you can implement effective solutions that enhance your fermentation outcomes.

Understanding the specific signs of fermentation issues is essential for timely intervention. Keeping a close eye on temperature and pH levels allows you to detect anomalies early on, potentially saving you from bigger headaches down the line. Tracking fermentation parameters aids in this process.

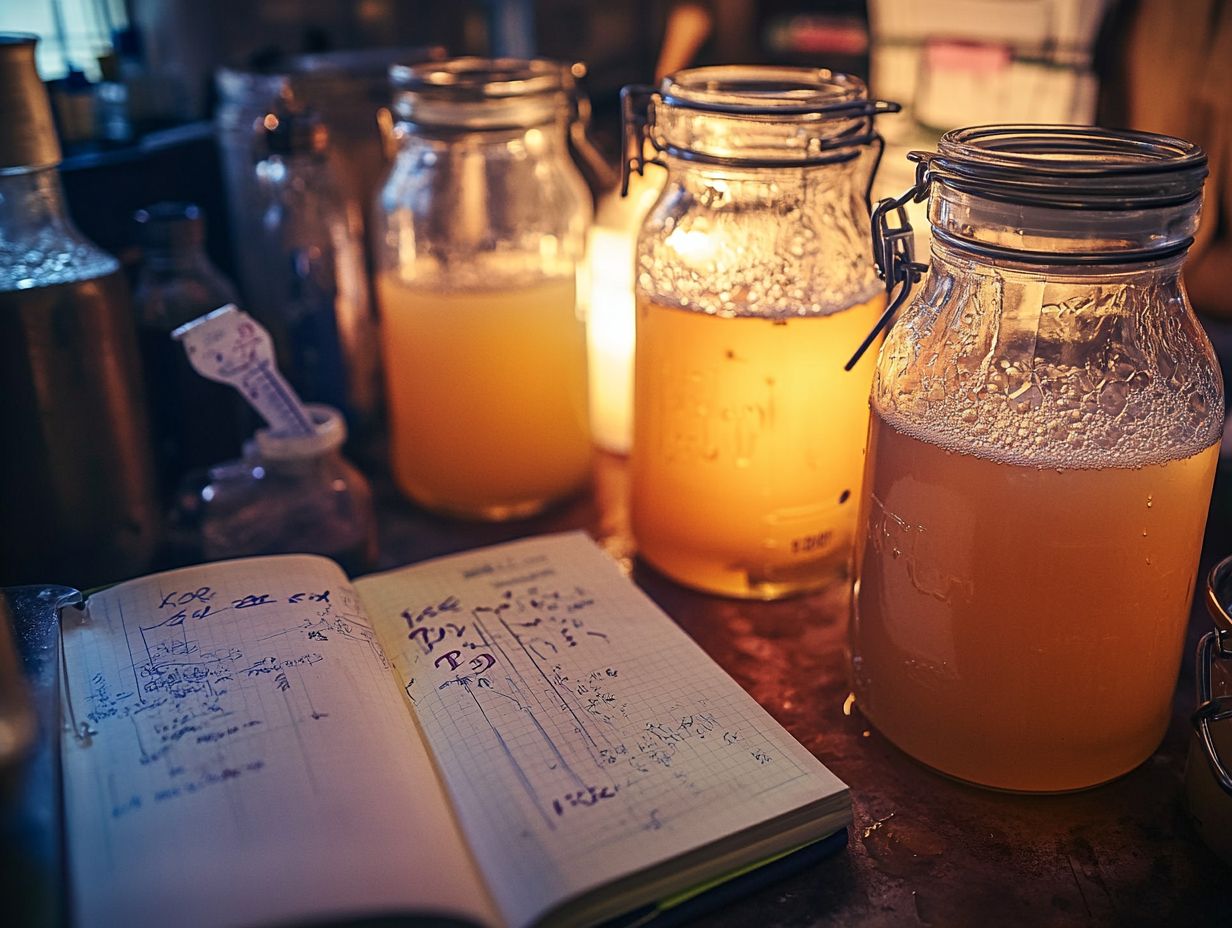

Maintaining a detailed log of your fermentation batches is beneficial. Note any deviations from expected performance. By promptly addressing signs of detrimental microbial activity or fluctuations in fermentation kinetics, you protect the integrity of your product while significantly improving overall efficiency and yield. Utilizing techniques like manual sampling and automated sampling helps maintain accuracy.

Incorporating techniques such as blending batches or adjusting nutrient levels is vital for rectifying potential problems. This leads to a smoother fermentation process and an exceptional final product. Maintaining proper biomass monitoring and growth curves ensures better control and optimization of the overall process.

Frequently Asked Questions

If you have questions or need further clarification, feel free to ask in the comments below! Applying these techniques will not only help you troubleshoot but also optimize your fermentation process.

How to Optimize Fermentation

Fermentation is a fascinating process where microorganisms, such as yeast or bacteria, convert organic compounds into simpler substances. This process is essential as it leads to the production of various products, including food, beverages, insulin, and pharmaceuticals. Understanding fermentation science is crucial for developing high-quality bioengineering techniques.

What are the key factors to consider when optimizing fermentation conditions?

The key factors to consider when optimizing fermentation conditions include temperature, pH level, oxygen levels, agitation, nutrient availability, and the type of microorganism being used. Advanced bioprocessing technologies and bioreactor systems significantly enhance fermentation optimization.

How does the pitching rate influence the fermentation process?

The pitching rate, which refers to the amount of yeast added to the fermentation medium, directly impacts the fermentation process. An optimal pitching rate ensures a healthy fermentation, maximizing yield and efficiency.

How do bioreactor systems enhance fermentation optimization?

Bioreactor systems provide a controlled environment for fermentation, allowing for precise management of conditions such as temperature and pH. This control leads to improved efficiency and consistency in fermentation outcomes.

How can I optimize my fermentation medium and determine the best nitrogen and carbon sources for my process?

To optimize your fermentation medium, it’s essential to analyze the nutritional needs of your microorganisms. This involves determining the best nitrogen and carbon sources that promote growth and productivity.

How can I control the temperature during fermentation?

Controlling temperature during fermentation can be achieved through temperature-controlled fermentation chambers, ice addition, or adjusting room temperature. Mastering temperature management is key to thriving fermentation!

What are the advanced bioprocessing technologies used for temperature management?

Advanced bioprocessing technologies, such as real-time monitoring and automated control systems, help maintain optimal temperature conditions during fermentation, preventing fluctuations that could affect outcomes.

What is the significance of the lag phase, acceleration phase, log phase, deceleration phase, stationary phase, and death phase in the fermentation process?

Each phase in the bacterial growth curve plays a critical role in the fermentation process, influencing overall productivity and yield. Understanding these phases helps in optimizing conditions for maximum efficiency.

How can temperature management help in preventing contamination during the fermentation process?

Effective temperature management creates an environment that minimizes the risk of contamination, ensuring that the desired microorganisms thrive while unwanted contaminants are suppressed.

What advanced bioprocessing technologies can be used for better temperature management?

Technologies such as automated temperature control systems and sensors allow for precise temperature regulation, enhancing the fermentation process.

What are the phases in a bacterial growth curve, and how do they impact the fermentation process?

Understanding the phases in a bacterial growth curve enables better control over fermentation conditions, ultimately improving yield and product quality.

What is the ideal pH level for fermentation?

The ideal pH level for fermentation depends on the microorganisms used. Generally, a pH range of 4.5 to 6 is suitable for most processes, promoting fermentation efficiency and yield.

How can different fermentation parameters be optimized for various metabolic pathways?

Optimizing fermentation parameters according to the metabolic pathways of specific microorganisms can enhance production and efficiency.

How can high-resolution data improve fermentation optimization?

High-resolution data allows for detailed analysis of fermentation processes, leading to more informed decisions and enhanced optimization strategies.

How do different fermentation parameters impact growth curves?

Fermentation parameters such as temperature and pH directly affect growth curves, influencing the overall fermentation process and yield.

How does bioprocess strategy contribute to optimizing fermentation parameters?

A well-defined bioprocess strategy integrates various fermentation parameters to achieve optimal conditions for microbial growth and production.

How can medium optimization improve fermentation efficiency?

Medium optimization targets the nutritional requirements of microorganisms, leading to improved fermentation efficiency and higher yields.

How does agitation affect fermentation?

Agitation plays a crucial role in ensuring microorganisms have consistent access to nutrients and oxygen, which are essential for growth and production.

What is the role of backscatter measurement in monitoring biomass during fermentation?

Backscatter measurement is a technique used to monitor biomass levels, providing valuable insights into fermentation progress and health.

How can manual sampling and automated sampling improve monitoring and control during the fermentation process?

Manual and automated sampling techniques improve the accuracy of data collection, allowing for better control of fermentation conditions.

How can backscatter measurement and optical density techniques assist in monitoring biomass during fermentation?

These techniques provide real-time insights into biomass levels, ensuring optimal conditions are maintained throughout the fermentation process.

What impact does agitation have on metabolite production and off-flavours?

Proper agitation enhances metabolite production while minimizing off-flavours, leading to better quality products.

What role does online biomass monitoring play in optimizing the fermentation process?

Online biomass monitoring allows for real-time adjustments to fermentation conditions, ensuring optimal growth and production.

How do I know if my fermentation conditions are optimized?

Monitoring key parameters and product yield can indicate whether fermentation conditions are optimized. Consistent results and high-quality outputs are good signs of success.

How can advanced bioprocessing technologies assist in fermentation optimization?

Advanced bioprocessing technologies streamline the fermentation process, providing tools for better monitoring, control, and optimization of conditions.

In summary, optimizing fermentation involves understanding and managing various factors, including temperature, pH, and agitation. By leveraging advanced technologies and strategies, one can achieve higher yields and better quality in fermentation processes!

What impact do nutrient requirements have on metabolic pathways during fermentation?

What role do Fermentis, ABPDU, and TeselaGen play in advancing fermentation technology?

What role does online biomass monitoring play in fermentation optimization?

The best way to determine if your fermentation conditions are optimized is by monitoring the growth and production of your desired product. If the product is being produced efficiently and at a high quality, then your fermentation conditions are likely optimized. Utilizing real-time data and continuous measurement can provide insights into the fermentation parameters.