5 Best Practices for Fermentation Monitoring

Contents

- The Art of Fermentation: Best Practices for Monitoring

- Understanding Fermentation: Key Practices for Success

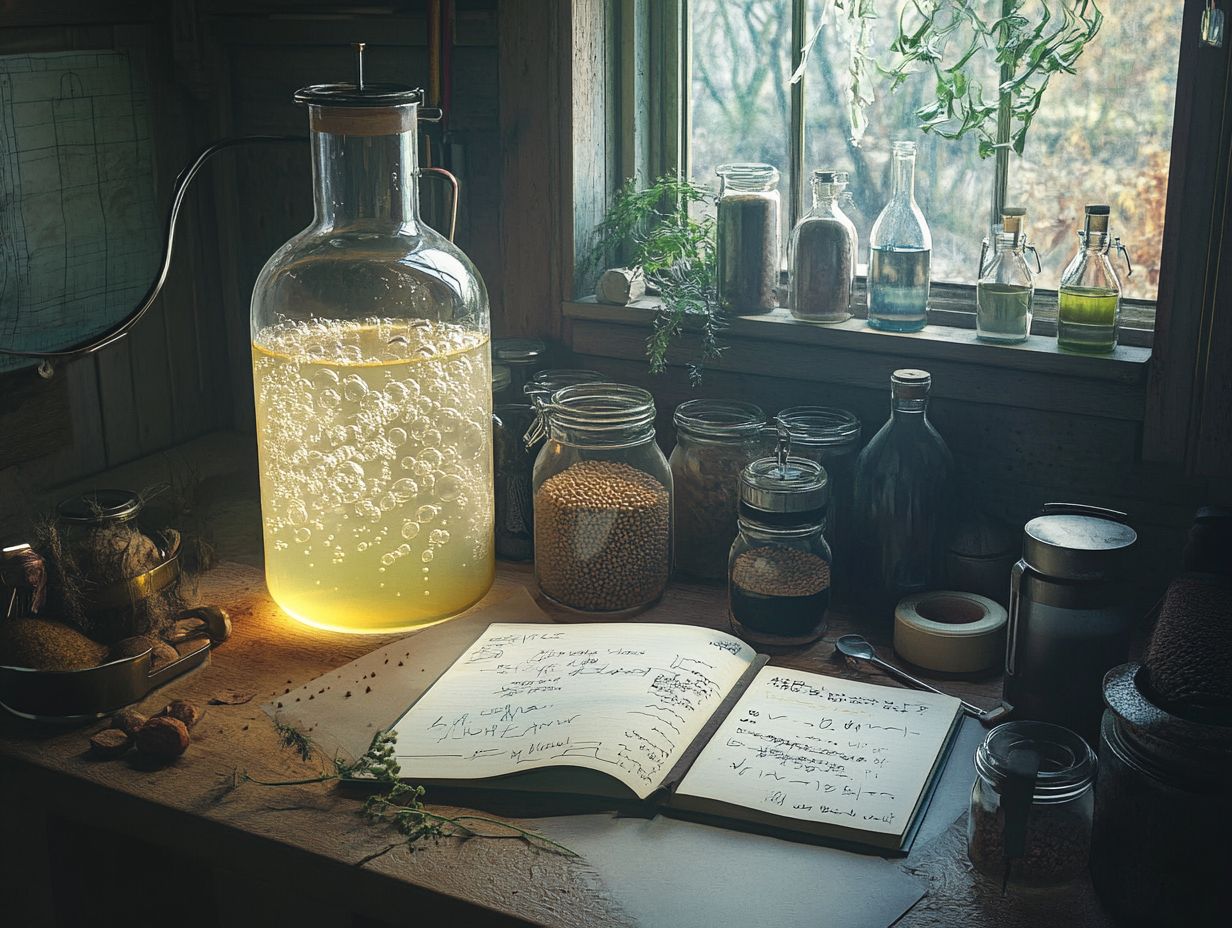

The Art of Fermentation: Best Practices for Monitoring

Fermentation is an intricate process that can profoundly influence the flavor, quality, and safety of your products. To achieve success, it’s essential for you to carefully monitor key factors such as pH levels, temperature, gas production, and microorganism interaction throughout your fermentation journey.

This article outlines five best practices for effective fermentation monitoring, emphasizing their significance and offering practical tips. Proper sanitation and understanding of microorganism interaction are also integral parts of this process.

Whether you re a dedicated homebrewer or operating a thriving business, grasping these practices will empower you to sidestep common pitfalls and elevate your fermentation endeavors to new heights.

- Regularly checking pH levels ensures that the fermentation process is proceeding as planned and helps prevent the growth of unwanted microorganisms.

- Monitoring temperature is crucial to maintain the ideal conditions for fermentation and to prevent the growth of harmful bacteria.

- Gas production is a key indicator of fermentation progress and can help determine when to move on to the next stage or when the fermentation is complete.

Key Takeaways:

1. Regularly Check pH Levels

Regularly monitoring pH levels is essential in the fermentation process of beverages such as beer, wine, and kombucha. It influences fermentation efficiency and ensures the quality and safety of your final product.

Whether you are using fermenters from Br u Supply or Unibr u, the importance of correct pH levels cannot be overstated. By maintaining the ideal pH, you can significantly reduce the risk of the growth of unwanted microorganisms, preserving the intended flavors and preventing potential health risks associated with improper sanitation practices.

A well-balanced pH environment supports yeast health, allowing them to thrive and ferment sugars more effectively. This leads to your desired alcohol content and flavor profile. Fluctuations in pH can hinder fermentation, resulting in off-tastes, suboptimal alcohol levels, or even spoilage.

To achieve precise measurements, it’s advisable to use high-quality pH sensors and regular calibration is crucial to ensure accuracy.

By taking these steps, you can promptly identify any deviations from the optimal pH range and implement corrective measures. This proactive approach allows you to have better control over the fermentation process, ultimately leading to a superior end product.

2. Monitor Temperature

Monitoring temperature during fermentation is essential for the health of the yeast, as it directly influences fermentation efficiency and the overall quality and safety of your brewed product. By maintaining proper temperature control, you can prevent unwanted bacteria from flourishing, ensuring that the fermentation process remains on track and delivers a clean final product.

For example, when brewing beer, it’s crucial to maintain a steady temperature between 65 F to 75 F (18 C to 24 C). Higher temperatures can introduce off-flavors, while lower temperatures might slow down yeast activity. Similarly, kombucha fermentation performs best between 75 F to 85 F (24 C to 29 C), allowing the symbiotic culture of bacteria and yeast to effectively convert sugars into acids and carbonation.

Fluctuations outside these ideal temperature ranges can significantly impact yeast performance, leading to an uneven brew and inconsistent flavors. Therefore, by understanding and managing temperature during fermentation, you not only achieve the desired characteristics of your beverage but also enhance the safety and stability of the final product.

3. Keep Track of Gas Production

Keeping track of gas production is crucial to your fermentation management, as it serves as a key indicator of yeast activity and overall fermentation efficiency. By monitoring carbon dioxide output, you gain valuable insights into the health of your fermentation process, allowing you to identify potential issues before they compromise your final product.

This is not just a box to check; it’s essential for maintaining the quality and consistency of your brew. You can employ various methods, such as gas traps or pressure sensors, to accurately measure gas release at different stages of fermentation. By correlating this data with temperature and gravity readings, you can diagnose fermentation challenges like stuck fermentation or off-flavors, enabling you to implement effective solutions.

Understanding the relationship between gas production and yeast activity is fundamental for optimizing fermentation time, enhancing product quality, and ultimately achieving brewing success. This understanding can revolutionize your fermentation efforts!

4. Check for Signs of Contamination

Regularly checking for signs of contamination is vital for preserving the integrity and safety of your fermentation process. Unwanted bacteria can introduce off-flavors and pose serious health risks. By identifying early indicators of contamination, you enable yourself to take corrective action and uphold proper sanitation practices, ultimately safeguarding the quality of your final product.

Look for common signs of contamination:

- Notable changes in smell: sour or spoiled odors

- Visual cues: unusual cloudiness or sediment formation

- Unexpected tastes: bitterness or sweetness that strays from your intended flavor profile

To mitigate these risks, it s essential to employ effective cleaning and disinfecting methods, ensuring that all equipment is thoroughly sanitized before and after use. Maintaining a sterile environment not only prevents contamination but also leads to a more predictable and enjoyable fermentation outcome.

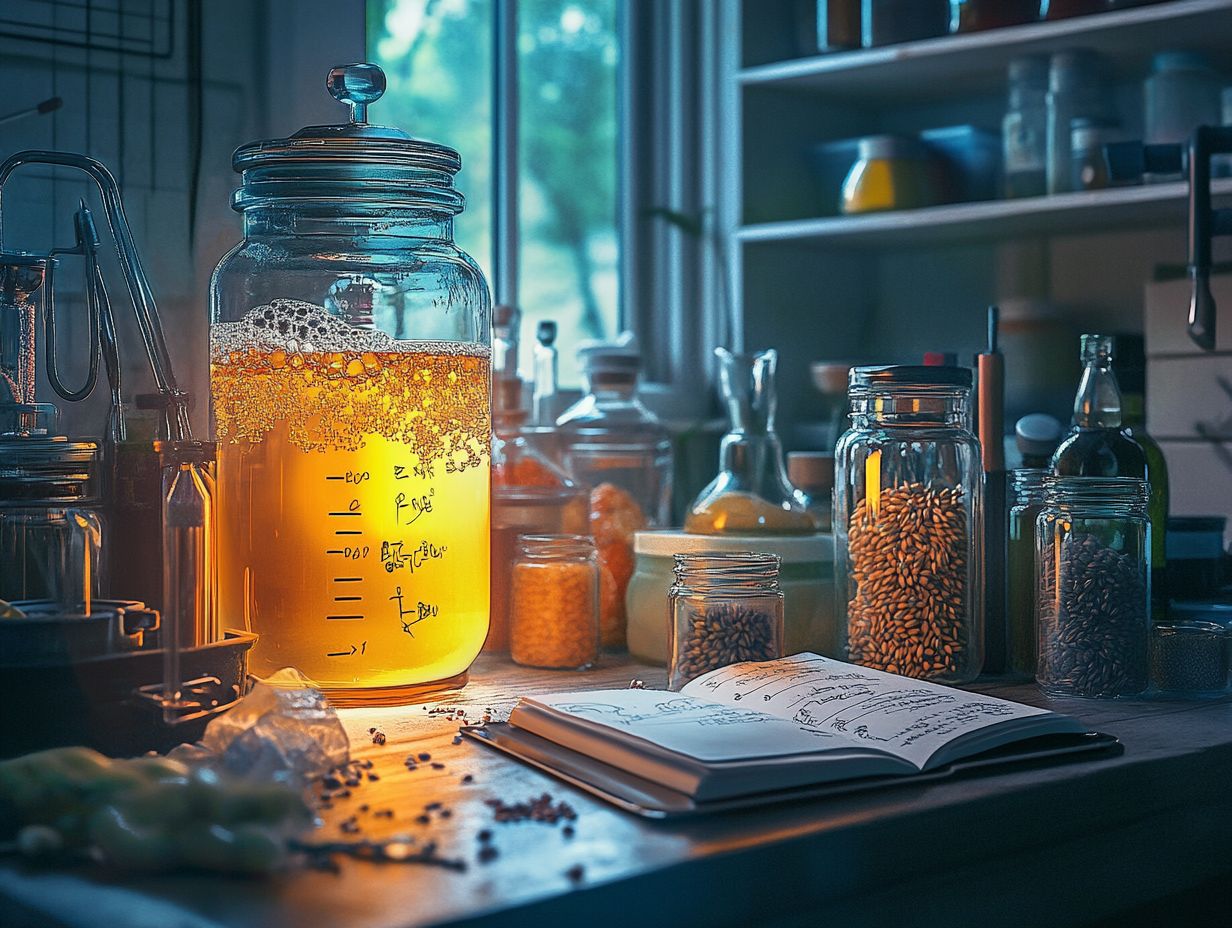

5. Record and Analyze Data

Recording and analyzing data throughout the fermentation process is crucial for optimizing your brewing systems and enhancing your fermentation management practices. By diligently tracking density of the liquid, temperature fluctuations, and gas production over time, you can uncover valuable insights into the dynamics of fermentation, enabling you to make informed decisions that significantly elevate the quality of your beer, wine, or kombucha.

Utilizing fermentation logs or specialized software can greatly simplify this data collection process. These tools not only automate the recording of critical parameters but also help you visualize trends and patterns that might otherwise elude your attention.

By employing these methods, you can pinpoint subtle shifts that may signal potential issues or the perfect moments for intervention. This thorough data analysis enables you to continuously refine your fermentation protocols, resulting in more consistent and exceptional end products.

As you gather more data over time, you build a rich repository of information that deepens your understanding, ultimately elevating your brewing craftsmanship to extraordinary new heights.

Why Is Monitoring Fermentation Important?

Monitoring fermentation is crucial for the success of your brewing system, as it directly influences fermentation efficiency, product quality, and safety standards. By keeping a close eye on the process, you not only identify potential issues early but also ensure that your final product meets consumer expectations and adheres to health regulations.

There are several key aspects you need to observe carefully. First, pH levels play a significant role in yeast activity; even slight deviations can impact fermentation. Then there’s temperature, which must be maintained within optimal ranges to facilitate proper fermentation. Gas production serves as an excellent indicator of yeast health and fermentation progress, while signs of contamination can jeopardize the entire batch.

By skillfully monitoring these factors, you can prevent health risks associated with spoilage or pathogens, ultimately achieving a consistent and desirable outcome. This meticulous oversight not only fosters confidence in product safety but also enhances your overall marketability.

Start monitoring your fermentation processes effectively today to ensure the best possible outcomes for your brews!

What Are the Key Factors to Monitor in Fermentation?

In fermentation, there are several key factors you should closely monitor: pH levels, temperature, gas production, and signs of microbial contamination. These elements work together to influence the quality and safety of your final product. By understanding how they interact, you can optimize your brewing processes and achieve superior fermentation results.

Maintaining the correct pH level is essential, as it directly impacts enzyme activity and microbial growth. Generally, a pH range of 4.0 to 5.0 is ideal for most fermentation processes. Temperature control plays a similarly critical role; any deviations can hinder yeast activity or result in undesirable flavors.

Monitoring gas production through airlocks provides valuable insights into fermentation progress, signaling either vigorous activity or potential issues. It’s equally important to keep a vigilant eye out for signs of microbial contamination such as off odors or unexpected cloudiness to prevent spoilage.

Using temperature logs, pH meters, and regular visual checks can significantly enhance your ability to manage these crucial factors. This proactive approach ensures a smoother fermentation journey and a more reliable outcome for your efforts.

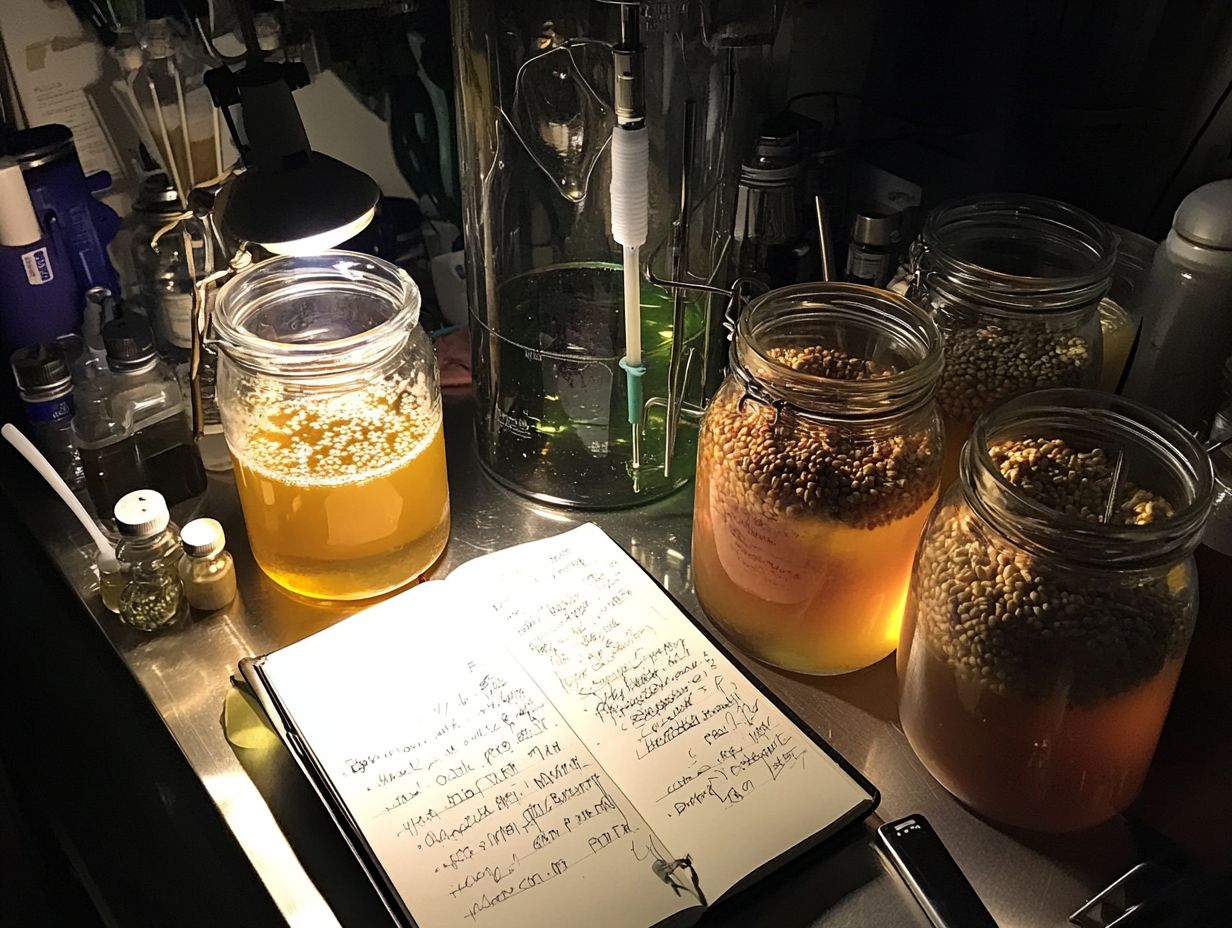

Essential Tools for Monitoring Fermentation

Unlock the secrets of perfect fermentation with advanced monitoring tools! Effective fermentation monitoring requires advanced tools and equipment. Sensor technology, fermentation logs, and pH meters are crucial for accurate data collection and analysis. Proper cleaning agents are also vital for maintaining a sterile environment.

Using the right tools elevates your fermentation monitoring, allowing you to track crucial parameters like pH levels, temperature, and gas production with remarkable precision. Advanced sensor technology and fermentation management software simplify the data collection process, offering insights that enhance your brewing practices. Whether you are into beer, wine, kombucha, or other ferments, these tools are indispensable.

By incorporating devices such as pH meters to measure acidity and temperature sensors to ensure optimal heat regulation, you can receive real-time updates on your fermentation process. Unibr u and Br u Supply offer excellent options in this regard, particularly with stainless steel equipment. Fermentation logs become invaluable assets for tracking historical data, enabling you to compare different batches effectively. These logs can also help in maintaining proper sanitation and avoiding unwanted bacteria.

This blend of technologies not only helps maintain consistency but also enables you to make informed adjustments as needed, improving your fermentation efficiency and overall product quality.

Ultimately, the synergy between these monitoring tools will lead to superior quality control, reduced risks of fermentation flaws, and a more efficient brewing experience. You will be able to perfect your craft with confidence. Understanding the interaction between microorganisms such as yeast and bacteria is also crucial in this process.

How Can Monitoring Improve the Quality of Fermented Products?

Effective monitoring during fermentation is essential for producing high-quality fermented products like beer, wine, and kombucha. It allows you to maintain optimal conditions for yeast and bacteria activity while minimizing health risks associated with microbial contamination. By closely observing key parameters like specific gravity and temperature, you can ensure that the fermentation process stays on track, resulting in a consistent and desirable final product.

The connection between monitoring and product quality goes beyond mere consistency; it also plays a crucial role in enhancing flavor and aroma. Adjustments made based on real-time monitoring data enable you to fine-tune variables like temperature and pH levels, which are vital for developing the taste profiles you desire. This is particularly important when dealing with Saccharomyces yeast strains.

By proactively responding to fluctuations in these parameters, you can elevate the overall consumer experience. Each batch can meet safety standards while also impressing palates with its rich and complex character. This meticulous attention to detail fosters trust and loyalty among your customers, ultimately enhancing their satisfaction with every fermented offering.

What Are the Common Mistakes to Avoid in Fermentation Monitoring?

Common mistakes in fermentation monitoring can lead you to suboptimal results. Key pitfalls include ignoring important parameters, failing to record data consistently, and misinterpreting the information you’ve collected. By learning to sidestep these issues, you can enhance your understanding of the fermentation process and ultimately produce safer, higher-quality products.

Diligence in data collection and analysis is crucial. Overlooking even minor fluctuations in temperature or a measure of acidity can jeopardize the entire batch. For instance, inconsistent sampling intervals may yield an inaccurate picture of fermentation progress. Implementing a regular schedule to monitor these critical factors is essential. Consider utilizing tools like fermentation logs or digital tracking systems.

Misinterpreting gravity readings can lead to incorrect assumptions about yeast activity and overall fermentation health. Both beer and wine brewers should be familiar with these readings. It s essential for you to understand proper measurement techniques and the significance of each parameter. This knowledge will enable you to make informed decisions that ensure a successful brewing outcome.

How Can a Business Incorporate Fermentation Monitoring into Their Process?

Incorporating fermentation monitoring into your brewing process is essential for ensuring product consistency and upholding quality safety standards. This involves avoiding microbial contamination risks and ensuring proper sanitation. By implementing systematic monitoring practices, you can optimize your brewing systems, identify issues promptly, and enhance overall fermentation efficiency, leading to a superior final product. This also helps maintain health standards for consumers.

To effectively achieve these goals, it’s crucial to invest in robust training programs for your staff. This ensures they grasp the critical aspects of fermentation and recognize deviations from desired parameters. Allocating resources to advanced monitoring technologies, such as automated sensors and data analytics tools, will enable you to track fermentation conditions in real time.

Establishing standard operating procedures (SOPs) will standardize your practices further. This enables your team to respond consistently and efficiently to any anomalies that arise. Consider incorporating nutrient supplementation as part of your SOPs. This structured approach supercharges your operations while nurturing a culture of quality assurance, ultimately enhancing customer satisfaction and strengthening your brand reputation. Safe and clean practices are essential to avoid off-flavors caused by contamination.

Frequently Asked Questions

What are the 5 best practices for fermentation monitoring?

Here are the top 5 best practices for fermentation monitoring:

- Regularly measuring and recording the fermentation temperature.

- Monitoring the pH level and making adjustments if necessary.

- Checking the sugar level to ensure proper fermentation.

- Conducting visual inspections for any signs of contamination.

- Tracking the duration of fermentation and noting any deviations from the expected timeline.

Using cleaning agents and maintaining proper sanitation also ensures the quality of your ferment.

Why is it important to regularly measure and record the fermentation temperature?

Regularly measuring and recording the fermentation temperature is important because it significantly affects the growth and activity of yeast, which is crucial for successful fermentation. Fluctuations in temperature can slow down or even halt the fermentation process, resulting in off-flavors or a stuck fermentation.

How does monitoring the pH level contribute to successful fermentation?

The pH level plays a crucial role in fermentation as it affects the growth and activity of yeast. Maintaining a proper pH level helps create an environment conducive to yeast growth and can prevent the growth of harmful bacteria that can spoil the batch of fermented product.

Understanding Fermentation: Key Practices for Success

What is the significance of checking the sugar level during fermentation?

Checking the sugar level during fermentation is important because it allows for the monitoring of the progress of fermentation. As the yeast consumes sugar, it produces alcohol and carbon dioxide. A steady decrease in the sugar level shows that fermentation is successful. If the sugar level does not change or increases, it may signal a problem.

Why should visual inspections be conducted during fermentation?

Keep your batch safe! By conducting visual inspections, you can catch contaminants early and protect your hard work. Look for any signs of contamination, such as mold or bacterial growth. Clean and disinfect to prevent contamination. Don t wait! Early detection can save your batch and ensure the safety of the final product.

How can tracking the duration of fermentation be helpful?

Tracking the duration of fermentation is important because it allows for the detection of any deviations from the expected timeline. This can indicate potential issues with the fermentation process and allow for adjustments to be made to ensure a successful and consistent final product.